“Alinaghian Dairy and Meat Company” Begins Phase Two of Smart Automation

Isfahan – In a continuation of its forward momentum in smart livestock farming, Alinaghian Dairy and Meat Company has initiated the second phase of its smart automation project, focusing on the feed mill. This follows the successful completion of phase one, which involved the online connection of the Pani nutrition management software to the Micron Tozin company’s indicators.

In a meeting attended by key representatives from Alinaghian Dairy and Meat (Engineers Asasi and Morataheb), Modiran Tahlilgar Sepahan, and Micron Tozin, the following points were reviewed for the smart automation of the feed mill:

– Smart detection of tank inventory: To prevent raw material shortages and optimize the ordering process.

– Automatic production of various rations: Aimed at increasing accuracy and reducing human errors in feed production.

– Analysis and review of premix and concentrate production: To ensure quality control and the correctness of ingredients.

– Smart management of loading and unloading: To expedite and make logistical processes more precise.

A crucial point in this phase is the complete integration of the system. Ration formulas are automatically received from the Pani nutrition management software, and after production, the relevant information is automatically logged back into the same software. This seamless connection creates a fully smart and automated production and management cycle, which can revolutionize feed consumption optimization and increase productivity.

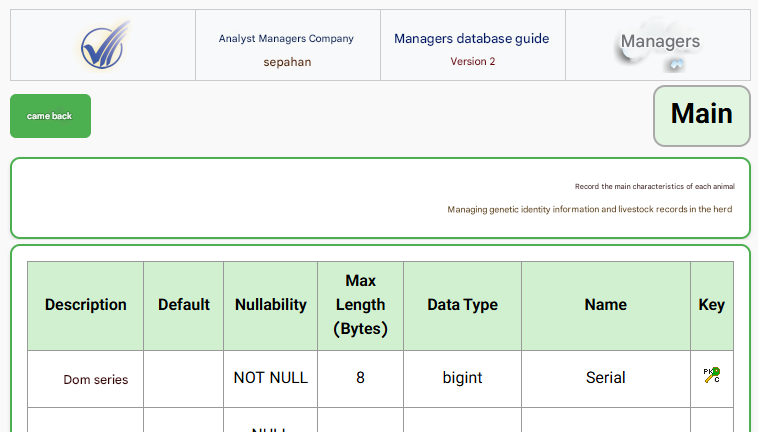

“Sepahan Dam” Livestock Company Takes a Step Towards Smart Automation

Isfahan, August 2025 – Sepahan Dam Livestock Company, which specializes in raising the specific Asef sheep breed, has initiated the process of smart automation on its farm to leverage new technologies.

During a meeting with the company’s managers, Engineers Basiri and Jafari, the various dimensions of smart livestock farming and its roadmap were reviewed. After gaining a full understanding of the benefits of this approach, the company took its first practical steps toward smart automation.

These initial measures include two key parts:

– Subcutaneous animal identification: This innovative method enables precise identification and tracking of each Asef sheep, helping managers to individually monitor health, nutritional, and production data for each animal.

– Use of the “Modiran Tahlilgar Sepahan” web-based version: The company will use online management and analytical tools to collect and process farm data.

This decision reflects Sepahan Dam’s commitment to raising management and productivity standards in Asef sheep breeding and can serve as a successful model for other specialized livestock farms in the country.

Astan Quds Razavi, a Pioneer in Smart Automation of Light Livestock in Khorasan

Mashhad – In a strategic and transformative move, the Astan Quds Razavi Agricultural Holding has connected all seven of its agricultural units in Khorasan province to the web-based “Modiran” software. This project is a major step toward the full implementation of smart livestock farming in the light livestock sector.

With the connection of these units, all light livestock breeding activities across the province will be managed and monitored online. This comprehensive software allows for very fast data entry and covers a wide range of management and recording operations.

Key advantages of this new system include:

– Increased speed in data entry.

– Wide scope of recording operations.

– Quick access to reports.

– Online monitoring.

This project not only demonstrates Astan Quds Razavi’s commitment to using modern technologies in the agricultural industry but also serves as a successful model for other large livestock complexes in the country.

“Pegah Fars” to Transform Herd Management with Two-Phase Smart Automation

Shiraz – Pegah Fars Livestock Company has taken a big step toward smart livestock farming by approving a contract for the simultaneous implementation of two phases of this project. These two stages mark the beginning of an innovative project aimed at improving herd management and enhancing animal health and productivity.

Phase One: Environmental Condition Monitoring with THI Sensors

In this phase, smart THI (Temperature-Humidity Index) measuring devices will be installed in the barns. These devices continuously collect data on the barn’s temperature and humidity and send it to the “Modiran” herd management software. This capability allows managers to control environmental conditions in real-time and prevent heat stress in the animals.

Phase Two: Animal Identification and Tracking with Smart Leg Bands

In the second phase, animals will be identified using smart leg bands. These bands provide multiple features, including:

– Detection of animal movement levels: Monitoring daily activity levels to enable early detection of diseases or estrus.

– Identification of animals in the barns: The ability to track animal movement.

– Access to animal records: By approaching an animal, its complete record, including health and production history, will be accessible through the “Modiran” herd management software.

The simultaneous implementation of these two phases will make “Pegah Fars” one of the most modern and efficient livestock complexes in the country and is a crucial step toward optimizing milk and meat production processes.